Short ROPP aluminum caps utilize Roll-on Pilfer Proof technology, the threads are formed by rolling the cap as it's installed on the bottle, providing anti-theft and excellent sealing properties.

Common product specifications show that the height of short ROPP aluminium caps ranges from 14mm to 18mm. For example, a 20mm ROPP aluminum cap might be around 14mm tall; a 28mm ROPP aluminum cap has two common heights: 15mm and 18mm; and a 31.5mm ROPP aluminum bottle cap is approximately 18mm tall. Common sizes for short ROPP aluminum bottle caps include φ20x14mm, φ22x16mm, φ24x18mm, φ28x15mm, φ28x18mm, φ31.5x18mm and φ38x18mm.

Short ROPP aluminum caps offer the following features:

- Excellent Sealing Performance:

Short ROPP aluminum caps utilize a rolling process to form the threads, which fit tightly against the bottle opening. Combined with the commonly included non-PVC inner gasket and other sealing materials, they provide an excellent seal, effectively preventing leakage, oxidation, and moisture. They are particularly suitable for products requiring a high degree of sealing, such as beverages and pharmaceuticals.

- Strong Anti-theft and Anti-Counterfeiting Features:

After opening, the ROPP aluminum cap's anti-tamper ring connects to the cap and undergoes destructive deformation, clearly indicating that the cap has been opened. This effectively prevents unauthorized opening or tampering during sales, protecting consumer rights.

- Safe and Environmentally Friendly Material:

Aluminum is inherently non-toxic and hygienic, ensuring it will not contaminate contents and meeting the hygiene standards of the food, pharmaceutical, and other industries. Aluminum is also highly recyclable, requiring less than 5% of the energy used to produce primary aluminum, significantly reducing greenhouse gas emissions and outperforming many other bottle cap materials in terms of environmental performance.

- Easy to Open and Close:

The short ROPP aluminum cap opens and closes with a simple twist, eliminating the need for tools. This convenient, reliable, and safe operation provides consumers with a positive user experience.

- Corrosion Resistance:

Aluminum exhibits excellent corrosion resistance and is resistant to rust. Even in humid or corrosive environments, the cap maintains its integrity and performance, extending the shelf life of the product.

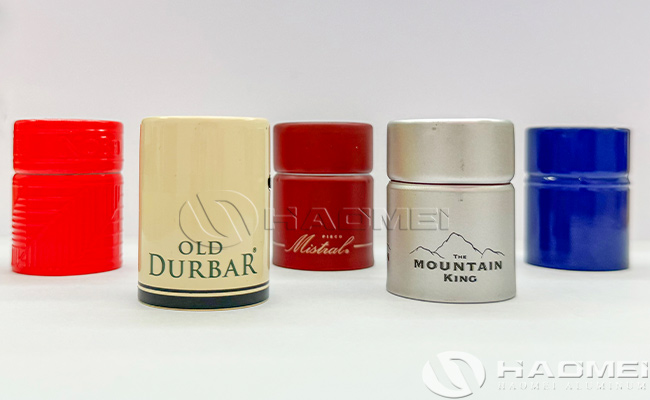

- Decorative Design:

The short ROPP aluminum cap can be treated with a variety of surface treatments, including anodizing, laser engraving, and embossing, to create a variety of colors, sheens, and textures, enhancing the product's appearance and brand image. It is particularly suitable for packaging high-end beverages, cosmetics, pharmaceuticals, and other products.

- Widely Compatible:

Suitable for bottle necks made of various materials, including glass and PET, short ROPP aluminum caps are highly versatile, adapting seamlessly to both recyclable and non-recyclable bottles.

Short ROPP aluminum caps have a wide range of applications, primarily in the following sectors:

- Beverage Industry:

Suitable for mineral water, natural water, non-alcoholic and alcoholic beverages, juice, functional beverages, and more. Beer, wine, and carbonated beverages are often sealed with short ROPP aluminum caps.

- Food Industry:

Suitable for packaging foods such as edible oil, ensuring food quality and safety.

- Pharmaceutical Industry:

Short ROPP aluminum caps are also used on glass bottles of some pharmaceuticals, providing a good seal and moisture-proofing, ensuring the effectiveness and stability of the drug.

When choosing the right short ROPP aluminum cap, focus on six key points:

- Matching the contents:

Select based on the sealing and corrosion resistance requirements of the contents (e.g., beverages, pharmaceuticals). For hot-fill products, additional consideration should be given to the cap's heat resistance.

- Aligning dimensions:

Accurately match the bottle neck diameter (e.g., φ28 for a 28mm neck) and maintain a cap height within 14-18mm based on the packaging design.

- Ensuring basic functionality:

Prioritize designs with easily breakable anti-theft rings, a good inner gasket seal, and moderate opening torque.

- Material and environmental considerations:

Choose aluminum that meets food/pharmaceutical hygiene standards, preferably recyclable options.

- Brand-matching:

Choose designs that support anodizing and clear printing to match the product's positioning.

- Controlling costs and supply:

Select products with the best value for money, prioritizing reputable suppliers with stable production capacity. Ensure compliance with relevant standards such as BB/T 0034-2017.

MESSAGE

RECOMMENDED PRODUCTS

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China