The 30x60 aluminum screw cap with EPE liner is commonly used for various liquid packaging applications, particularly in the food, cosmetics, and pharmaceutical industries. 30x60mm generally refers to a cap diameter of 30mm and a height of 60mm, suitable for standard threaded bottle necks (such as GPI/SPI 30mm). The screw type is ROPP (Roll-On Pilfer-Proof), and the pitch and number of threads can be customized to suit the bottle neck specifications. The EPE liner (expanded polyethylene foam) provides a seal and protects the bottle contents.

Materials and Processing

- Aluminum screw cap body:

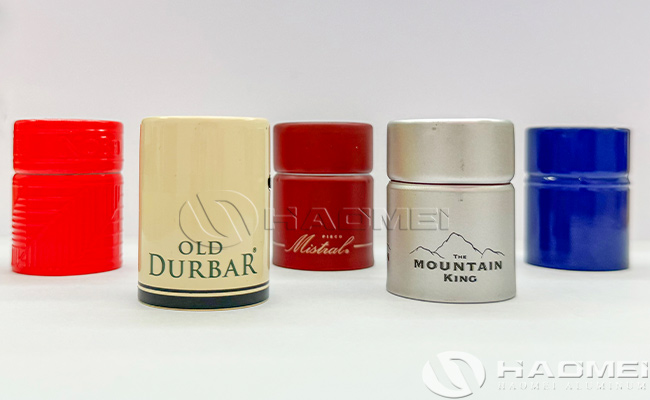

Constructed from 8011-H16 aluminum alloy coil/sheet/strip. The surface can be electroplated, painted, or printed with a logo. Custom colors (such as matte black and champagne gold) are also available.

- EPE Liner:

Choose EPE lining with a thickness of 5-10mm (standard protection) or 15-30mm (high protection) and a density of 20-35kg/m³. It combines flexibility with resilience (>90% recovery rate after compression) to ensure a seal and shockproofing. After die-cutting, it is embedded into the bottle cap to provide cushioning and sealing. The material is FDA and GB 4806.7 food-grade certified, suitable for direct contact with food or pharmaceuticals.

- Surface Treatment:

It supports offset printing, roller printing, UV printing, or hot stamping, and the side can be laser engraved or inkjet-printed.

Features and benefits of aluminum screw cap with EPE liner:

- Excellent Sealing Performance

The EPE lining provides an excellent seal, effectively preventing leaks and external contamination, ensuring product safety during transportation and storage.

- Moisture and Corrosion Resistance

EPE material has excellent moisture resistance, effectively isolating moisture and protecting the bottle contents from moisture. Furthermore, the aluminum material is highly resistant to corrosion from various chemicals.

- Lightweight and Durable

Aluminum bottle caps are lightweight and durable, making them suitable for long-distance transportation, reducing transportation costs and the risk of damage.

- Environmentally Friendly and Recyclable

Our aluminum bottle caps are recyclable, meeting environmental standards, and helping customers achieve their sustainability goals.

- Aesthetically Versatile

Aluminum bottle caps can be treated with a variety of surface finishes, such as anodizing, spraying, and printing, to meet the personalized needs of different customers and enhance product competitiveness.

Customization Process

- Requirement Communication: Clarify dimensions, thread parameters, EPE thickness and surface treatment requirements.

- Prototype Confirmation: The 30x60mm aluminum caps supplier will provide 3D samples to verify seal performance, opening force, and appearance.

- Mass Production: Delivery within 20-40 days after contract signing (depending on the MOQ).

- Quality Testing: Pass drop tests, pressure tests, and hygiene indicators (e.g., heavy metal migration ≤ 0.01 mg/kg).

Cost Structure

- Molding Fee: Initial mold opening costs are approximately 700-2,000 dollars (depending on complexity).

- Unit Price: Aluminum cap + EPE liner approximately 0.8-1.5 RMB/piece (MOQ 100,000 pieces), FOB.

- Surface treatment surcharge: Printing or plating adds 0.1-0.3 RMB/piece.

- Lead Time: Regular orders are 20-30 days, and expedited orders can be shortened to 15 days (at an additional cost).

For more information, samples or quotes of 30x60 aluminum screw cap with EPE liner, please feel free to contact us. We look forward to building a long-term partnership with you and working together to achieve market success for our products.

MESSAGE

RECOMMENDED PRODUCTS

PRODUCTS

CONTACT US

Add:Zhengzhou, Henan, China